Process Engineer

DOGA is a growing multinational company with over 60 years of experience in the development of customized projects for various industrial sectors. With a strong focus on R&D, we established ourselves as a key player in the creation of advanced solutions by combining electronic and mechanical engineering.

We design and manufacture our own products, which allows the company to maintain full control over quality and innovation. With a global presence, we have subsidiaries in Italy, the United States, Mexico, Brazil, China, India, Morocco and Japan, and distributes its products to over 70 countries.

We are seeking a Process Engineer to join our Mexico Plant, responsible for ensuring process stability and product quality on our wiper-system assembly line for truck programs. The ideal candidate is a hands-on engineer who combines a methodical approach to continuous improvement with strong technical knowledge and a proactive attitude toward problem solving.

ESSENTIAL TASKS

- Own day-to-day process performance: monitor and improve cycle time, takt adherence, changeover time, FPY, and OEE in collaboration with the Production team.

- Deploy, maintain, and continuously improve Work Instructions, Control Plans, and process parameters handed over from Spain.

- Perform line calibration and parameter checks, basic PLC/HMI diagnostics, and escalate complex issues to the central engineering team.

- In coordination with Maintenance, define and execute the Preventive Maintenance Plan (PM checklists, spare parts, backups, utilities checks) to prevent line-down events.

- Use CAD 3D/2D tools (SolidWorks, CATIA, Inventor, or similar) to design and update jigs, fixtures, layouts, and workstation ergonomics for continuous improvement.

- Lead pilot builds and Run@Rate rehearsals, identify losses, and implement improvements through SMED, 5S, and Poka-Yoke methodologies.

- Maintain accurate and up-to-date process documentation, ensuring PPAP readiness and supporting Quality with GRR and capability studies.

- Coach operators and supervisors on standard work, changeover routines, and troubleshooting to sustain operational excellence.

PROFILE REQUIRED

- 3+ years of experience in process or production engineering (preferably in the automotive industry).

- Proficiency in CAD 3D/2D design for fixtures and layouts.

- Solid understanding of PLC/HMI basics, line calibration, and electrical/pneumatic systems.

- Familiarity with takt/cycle analysis, SMED, 5S, and problem-solving tools.

- Fluent Spanish and working proficiency in English (for technical documentation and training in Spain).

- Strong hands-on mentality, ownership, and sense of urgency.

Nice to have:

- Experience with APQP, PFMEA, control plans, and PPAP.

- Knowledge of torque control, functional testing, traceability, and MES/ERP systems.

- Awareness of MSA/GRR and collaboration with Quality.

WHAT WE OFFER

- 🚀 Join a Thriving Company: Work for a rapidly growing and strategically positioned company.

- 👋 Dynamic Team Environment: Collaborate in active work environment alongside a team of highly qualified and dedicated professionals.

- 🌍 Inclusive Culture: Thrive in an inclusive culture that values diversity, where all individuals, regardless of background, gender, sexual orientation, abilities, or gender identity, feel respected and valued.

If you are interested in joining our DOGA team, do not hesitate to apply. We will be happy to talk to you!

- Department

- Industrial

- Role

- Plant Engineering

- Locations

- DOGA MEXICO COMPONENTES

Colleagues

DOGA MEXICO COMPONENTES

Our Mission

Windshield Wiper & Washer Systems:

To be the global leader in wiper & washer systems for small and medium size series.

Drive Systems:

To support customers with innovative DC motors and geared motors solutions up to 48 volts.

Tank Systems:

To be a global leader in innovative solutions for plastic tanks and other plastic blow-moulded parts, for small and medium volume series.

Window lift systems:

To provide customized solutions for window lifters for small and medium volume series.

Complementary systems:

To increase our added value to our customers by offering complementary products: air systems, gas springs and mirrors.

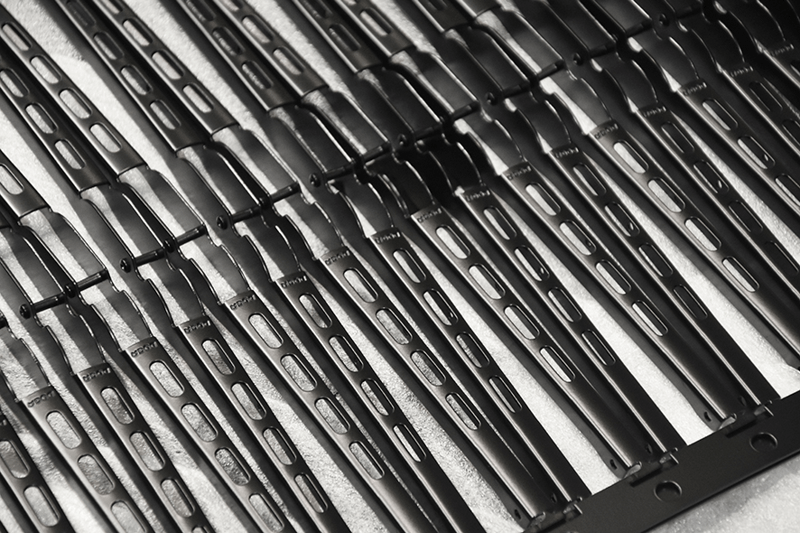

Stamping:

To be a global partner with our customers in process development and manufacturing of stamped and assembled parts.

About DOGA

HISTORY

DOGA commenced its business activities in Barcelona in 1958.

It began by manufacturing windshield washer/wiper kits, later expanding into direct-current motors (for motor vehicles and industry) and the stamping of welded kits.

QUALITY & SERVICE:

DOGA knows the importance of ensuring a high level of customer satisfaction and this has become the main objective in all areas and departments of our Company.

Committed with the planet, we work towards a sustainable environment. DOGA has chosen to act respectfully towards the environment within all countries we operate.

Devoting some effort to improve our social environment has a positive impact on the people, our most valuable resource. If our environment grows, we will grow with it.

R&D - OUR TECHNOLOGY

With a team of more than 60 people, at DOGA, we focus on the development of projects in our Technical Centre.

We have extensive know-how in terms of the development and production of automobile components that are specially designed for OEM applications, and the execution of each project is given an individualized treatment and assigned a management team in order to achieve maximum performance.

Each system is the result of a unique project that has been developed specifically for each application.

Already working at DOGA?

Let’s recruit together and find your next colleague.